Live video of a work space could one day replace the measuring tape and all kinds of layout tools. The antique trade secret known as "Camera Lucida" is employed with modern 3D CAD. Ideally a builder would have goggles with video access to both strategically placed cameras of work scene and to the actual computer interface of a 3D work plan, which would vary according to the work project and could take forms. Ilustrated for the era of early personal-computers, this page presents ongoing research into direct use of personal computers in construction and fabrication work-- Ultimately, very compact equipment could evolve and perhaps apply to any kind of physical labor which uses measuring devices or patterns. Future equipment will be much easier to use than the experimental research presented here.

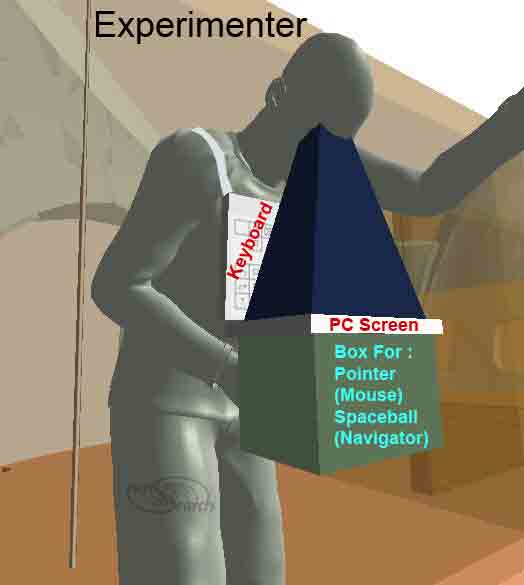

Artistic architecture is most in need of the currently implemented Cadmera methods. (Examples can be found here). A good brand of CAD software works as the lay-out and measuring tool for concrete, carpentry and other kinds of live work. An organic style of architecture is demonstrated here. The first picture depicts a make-shift method to use a generic PC, strapped to a user. Gaming goggles might work more conveniently if the resolution is high enough along with smaller PCs even the present MacMini.

This page retains

earlier Cadmera development history below, to show the progress of this research.

Therefore the presentation will be a little crude. I've not gotten around

to mocking up more ideal builder-equipment than the illustration above but

do intend to. Latest News Flash-- Here is another great lens released late

in 06. A great super-wide angle lens which produces pictures without distortion.

I'm

not

sure

if a single definitive name was given to the lens unit, but it seems

primarily

destined for manufacturers of security systems. ZD net may still have a

fairly concise article--

http://bacteriologists/emerging

tech/index.php?p=425

The source for the lens--

http://www.nanophotonics.co.kr/html_shop/en_shop_list.htm

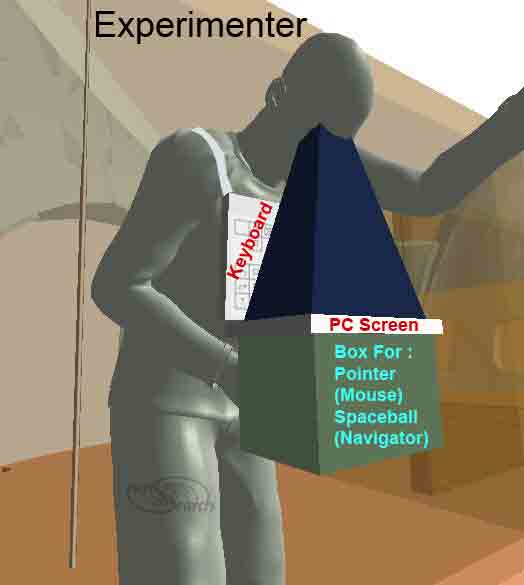

The next picture shows a popular natural shape modeled in 3D CAD, followed by general procedures to build it in real life.

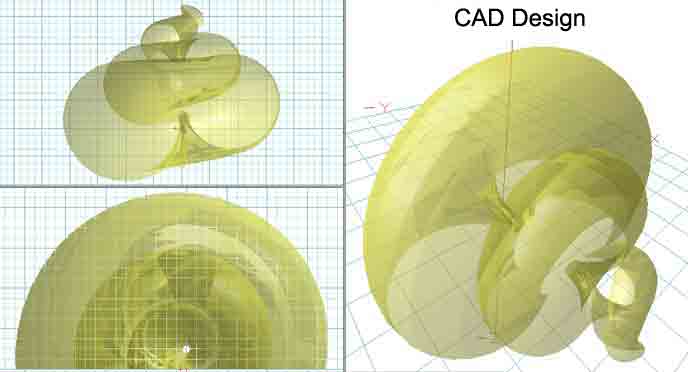

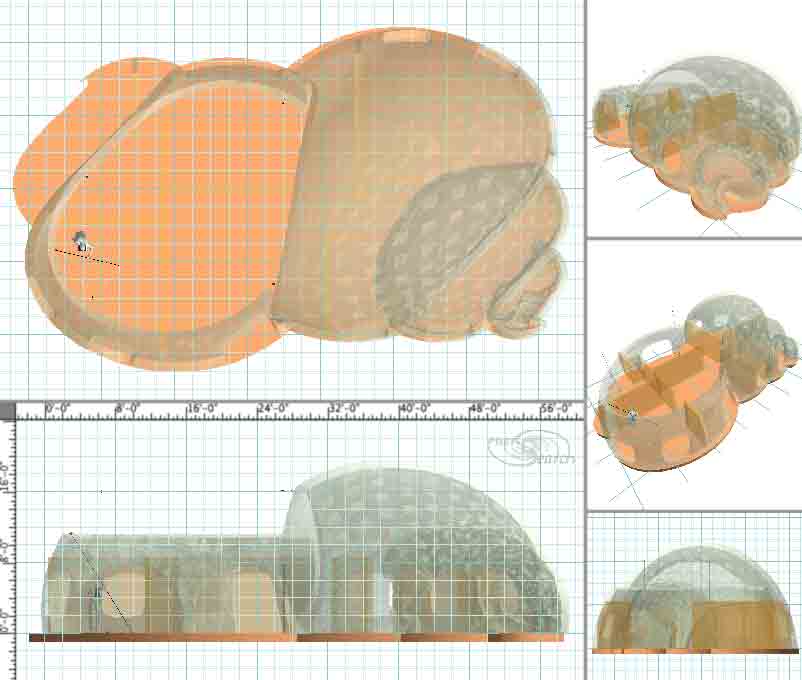

Next is shown a CAD design adaptation using the same shell for a house. Semi-transparent rendering intends to provide abbreviated clarity.

The same CAD model continues below. It is rendered "in the rough", saved in extra-low resolution, just to outline the Cadmera concept. More information and pictures are available by request, (as time may permit). Priority is given to hopeful projects.

The model above depicts the left side of house under construction. The Cadmera method is used to find coordinates in real space. Cameras are placed at somewhat orthogonal positions. Several cameras can be used simultaneously with the PC. Diverse cameras and connections to PC are available, such as by "Fire wire", USB "WiFi" etc.. The wireless type might prove preferable. I have tried a cheap solution: "Fire-i" cameras with 3rd party display software of the security-type and on Mac OS X system. Yet better lenses should provide for much greater accuracy.

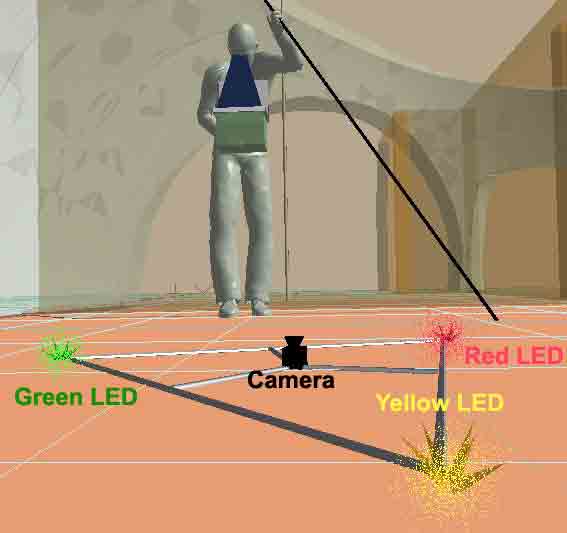

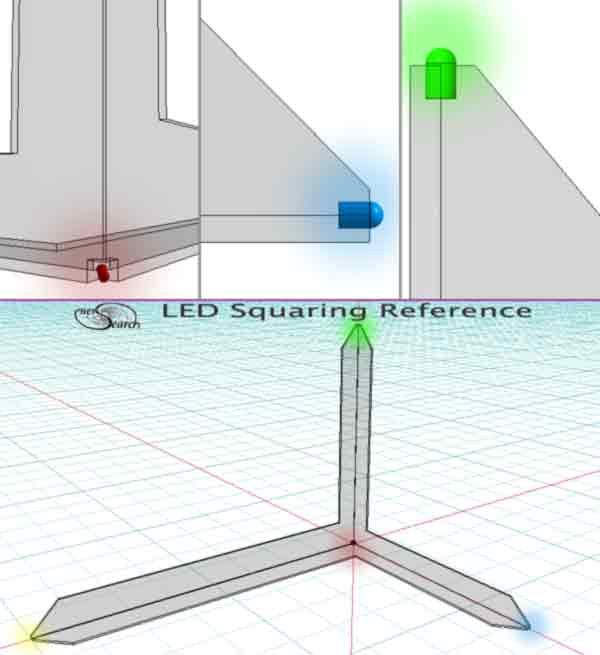

Next picture below depicts experimenter at work with a Cadmera calibration reference triangle on the floor. It is a simple frame with colored LED lights. A camera is also fixed at it's center (Corresponding to a CAD reference model). Calibration can be achieved simply by flying around in a computer model (with the perspective set to match that of the camera), until the CAD reference triangle does match the real reference-triangle on the floor. (These view matches between real and CAD are saved for continuing work).

The modeling should be done first, with a good 3D setup. In fact it is actually advantageous to use good 3D software which supports use of the Spaceball, a 3DCAD-navigating device. My trusty software is formZ which supports 3D navigation along with multiple windows. I use an OS X system software called WindowShade to make formZ windows semi transparent. This is the element of Camera Lucida, here made digital. One can now see a reference drawing or 3D model, superimposed upon corresponding, multiple views of a work space. As real concrete is added, it can even be placed according to the model, without using paper plans and measuring tapes. (An interesting method for building with concrete and Cadmera methods is on this page, still due to be updated to include this model).

The next picture below Shows that the experimenter is checking the wall accuracy. In a real job, the builder could check placements live. In place where the brick or block is placed. (Pending better wearable equipment). The real-LED, mounted on a pole is now seen through the cameras and within the 3D-software. For clarity, one can use a flashing LED, the smaller the better.

A great feature in formZ 3D modeling software is the ability to save unlimited views and to work with a graphical representation of the views. FormZ also has a window tool to assist matching perspective views. It's camera position can be manipulated as a CAD object or ultimately assigned to live cameras and otherwise retain perspective angle while navigating fly-through views. However, these inventive Cadmera techniques are not familiar to most CAD users or even formZ tech support. Still a further possibility is to use new features in formZ 6.x which allow live video to become projected on objects within the formZ model. This might allow a persons real workspace to be projected into the CAD model live. In other words the real-world video would be a back drop in the model so a builder could see real world progress inside the virtual model. Verify that what is built in the real world, in fact matches the model.

(Earlier Cadmera research follows below).

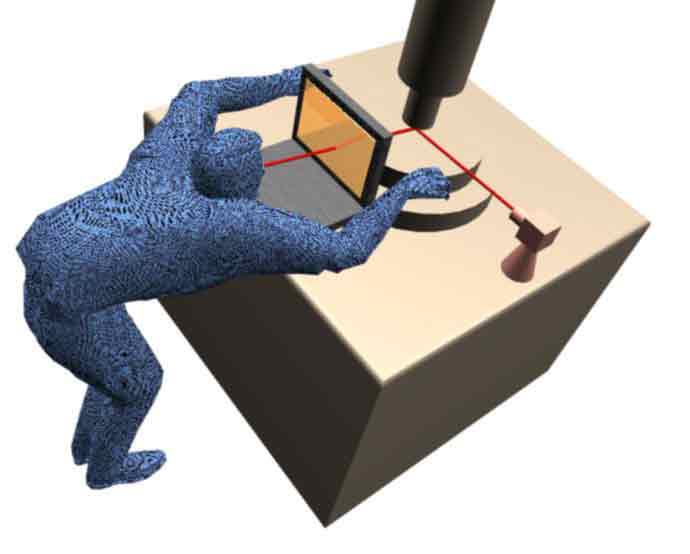

One camera and a semi-transparent lap top screen gives two views for centering machines like drills and punches. A semi-transparent screen displays the camera view superimposed over real view of. Combining both views together greatly improves aligning or centering. This is not possible with one view alone.

Placement of multiple cameras in a grid could potentially create views without perspective. Views without perspectives are essentially those used in traditional building. Having live-updated views of physical work allows the computer to be the final judge of all physical measurements. Today's computer gear already achieves this, although it is not widely appreciated. It is readily adaptable to all building but does need careful implementations.

Three adequately placed cameras alone is sufficient to computerize models . Perhaps even one camera could be moved around many viewpoints, with images saved for a multi-view compilation. A perspective-free image could then be processed and used in CAD work.

__

__

-------------------------

The cadmera concept came to me in 2003

First html webpage was started in 2004:

Digitizer Aided Building

Raster Aided Vectors!

Camera Lucida

Input-Output Digitizing / Computer Aided Craftsman / Computer Aided Labor

By Bo Atkinson

Live, real world measuring and layout is possible through CAD processing.

Experimentation presently requires CAD skills. Nevertheless automated

systems could vastly upgrade unskilled laborers. Otherwise CAD is

by far outpacing physical building plan execution. CAD (computer aided

design) could improve almost

any

layout

or measuring

work in real world

construction. The needed

ingredients already exist but are blocked by specialization.

Specialization

limits valuable potentials. Key service sectors are lost to CAD marketers.

There is also a significant loss of brick and mortar productivity.

Art Or Science?

The apprentice, laborer, and craftsman all could significantly boost production with CAD used directly in live measuring and pattern work. CAD could close the gap of uncertainty between specification and physical execution of customized work. CAD could even measure "on the fly" in order to replace the measuring tape . Traditional measuring and layout tools slow down and complicate customized labor. Specialized laboring is typically enough of a feat of physical exertion, of poise and of execution. A large sector of the productive population possesses untapped spacial-geometric ability. These qualities combined, offer a marketable dream to computer developers.

Multi-cycle Photographic Interaction With CAD

A tool set is emerging , (needing little user training), which can measure and gauge movement of a marker between successive photos. Electronically linking the mark in the real world with the CAD plan improves accuracy. The same mark can be the cutting position of a real world tool or a gauge for positioning work materials, even bricks and mortar.

Photographic interaction with 3D CAD has not yet been promoted for common labor. Craftsmen and laborers are independently beginning to learn about computers as work tools. From layout of cutting patterns to framing structures, CAD can readily adapt directly through photos or video. The scope of CAD applicability is already so wide as to have blinded earlier recognition of these potentials. Relatively little further development could greatly improve computer aided construction, (a market windfall on all sides).

Software Examples

Perhaps most suitable are fire wire and USB cameras. Live video of work scenes can be delivered to a computer window. An example of software which can display multiple live windows of a work scene is SecuritySpy. It is presently promoted as a security software, however it will accurately display multiple windows. For example: four windows can provide critical 3D orientation information. The CAD model likewise can be displayed in four matching windows on top. CAD , for example formZ, can display four windows. All of which can be verified against the physical markers and materials of the laborer or craftsman. The formZ window can be made partially transparent to allow this viewing of two softwares simultaneously. The real work world and the CAD model are aligned, one step closer to using CAD as a real world measuring tool and as a building plan, all combined.

More Essential Methods

A number of work site viewpoints orient a CAD model. Digital camera images can feed a CAD program accordingly. Systems could vary according to scope, but enough overlap exists for common tool components. Cameras can be mobile with widely moving tasks or can remain fixed in particular positions. External triangulation of real, live viewpoints and markers can match CAD coordinates for real time patterning and fitting of work. Distortion of specified lens is matched through CAD perspective views. Key to this proposal, tiny, bright LED marker lamps are placed in the work scene. (LED means light emitting diode). Key work-scene points are matched to CAD coordinates. Cameras and/ or LEDs may mount on particular tools, may attach to workman garb or to building materials. LED markers also hold CAD orientation as camera views are switched respective to real world work in progress. Lights nearly the size of a pencil mark or larger lights may be packaged singly or multiply. A squared "LED space" example is visualized below, potentially useful for checking camera readings

Proposed Goal: The interminable measuring tape could be replaced with two or more LEDs mounted on a square, gauge, push pin, magnet, or hook, ect... Bubble levels, plumb bobs and transits could essentially be replaced. Human fumbling errors are removed. Mental focus is enhanced. Even active tools like a landscaping rake or concrete screed could usefully incorporate cheap LEDs . CAD could track live tools to inform user of physical work (progress) status. Spherical camera housing in signature colors could help other cameras pin point each other camera-eye-point location. A wide range of trades could adapt to one common product base. CAD-camera: "CADmera"

Additional Experimental Implementation

Following are further examples, emulating said method with a readily available 3D CAD software. To test these concepts today, an experimenter can down load a formZ demo version and test many of these concepts. It matters not if 3D software is not advertised for these uses. Other softwares can be web searched and many offer trial demo versions.

The perspective view angle of a digital camera can be matched in the CAD window. Perspective views may prove satisfactory for some kinds of construction. A variety of concepts to improve this approach follow.

In formZ, the interactive shader called "Open GL" displays digital camera pictures very well. Thus real time work can display as an "updated slide show" behind CAD models which are also true to the camera perspective. Although formZ is not streamlined for automatically changing images, (updating real world views), such wizardry may become demanded through pluggins.

The "live camera image" is color mapped to a nominally rectangular CAD object, (equal to camera's pixel aspect ratio). As many "snapshots/ slides" as might be desired are storable, as normal images. Each such "snapshot/ slide" may or may not be useful for work history or for repeated tasking. Continuous image updating with consequent deletion of prior image is more appropriate for other circumstances.

Each view is displayed within a CAD window frame. formZ can display many windows simultaneously. Four windows has been found very helpful for general 3D modeling clarity. Experimenting with diverse uses could seem daunting, but efficiencies are recognizable with ample consideration. The interface of formZ is already highly customizable through user preferences. Diverse work environments are easily matched through customizing formZ interface. Furthermore, keyboard shortcuts can be personalized for many commands. Customized uses can be independently saved and latter re-invoked to demonstrate diverse customizations.

Narrower perspective view angles provide less linear distortion. Telephoto lenses provide narrower perspectives. It is usually not possible to use telephoto lenses due to the required distance needed to get the full work space in view. Therefore another system that may be employed is the "telescopic array". Ordinary perspective lenses may be grouped together in an array. A "top" (or birds eye view) of a construction site could be obtained by wide to medium angle cameras mounted on top of poles looking down. The resulting perspective views may then be both stitched and morphed together to reconstitute a narrower view angle. Ideally this approach could work towards an orthographic or axonometric view angle.

Even without these advances multiple views can be used manually today, in an exploration of tomorrow's tools. Practical implementation is available at several levels. Lower costing experimentation might use an computer with cable connections to cameras. (Alternatively, manually transported memory cards could update the CAD views.)

Dream-Tool Packages

Advancing innovation can use wireless technology for connections. A lap top computer which could attach to a workman's belt introduces portable usage. A stationary LCD projector could project work patterns to the material for cutting or fastening without the use of traditional markings, tracings and the like.

Reaching higher up the wish list, VR (virtual reality)

goggles could replace both screen displays and

projectors. Seamless

CAD updating

in a project

is feasible without user updating of views. The

LEDs used as markers could be

signature identified

by the software or hardware. Color/ frequency coded

LEDs and patterned strobe coding could allow many tracking points to be

addressed and a complex

structure

to be completely

and technically tracked from CAD to finish.

An important milestone is addressing a CAD system

through physical, customized work itself and

not exclusively

as a virtual model. Semi-see-through

goggles should allow matching human vision with

virtual CAD windows. Tasks like

cutting patterns with powered hand tools could

display the pattern directly

through

the goggles, given automated updating. Confusion

of task assignments to laborers is completely

removable. Both

an employee or an independent

worker

can operate

with greater confidence.

Highly portable computer equipment to mount on

workers and camera devices to mount on goggle/

helmet rigging

is practical.

An experimenter

would

need to customize

and adapt commercial products, but this is

available to experiment with today. Virtual reality developers

sell a variety of

equipment which is

experimentally

adaptable for craftsman, foreman, artist or

handyman. These examples should confirm that relatively

little development

will go a long

way.

Triggering

The visual indicator called "snap"(virtual, targeted touching), has long been in CAD. Real world "snapping" is feasible for CAD in various ways. Since LEDs shine "monochromatic light", (one narrow band of color), there is a natural possibility of 3D CAD snapping to those narrow bands of lights. This and other devices promise to orient 3D CAD with real world work.

Another device for "hand free" operation and for keeping eyes on real world work is audio output. One example is sometimes used for "computer aided inspection" (CAI). A $10000 digitizer arm sounds off increasingly louder as a user moves it's pointer close to objects of a linked 3D model. This is an admirable feature for complex shaping and positioning according to engineering plans. Digitizer arms however restrict reach to the digital arm's length.

By contrast, camera interfaced CAD, has a much longer reach potential. Also, handyman and laborer tasks are satisfied with far less accuracy, than with hi tech engineers. So cruder, cheaper implementation eases product development. In the meantime while experimenters wait for developers to follow, there are some small tricks.

Instant low cost improvisation

enables a crude "audible snap". A simple,

adaptable photo sensitive alarm could

be "taped on to" display screen,

(perhaps in a corner). The sensor would

be closely focused on the "zero" of

the active 3D CAD plane. When the 3D

CAD cursor snaps "off" of CAD

plane and on to a CAD surface snap, the

said "zero" display

would change to the numeral values of

the snap. This display change could trigger

a photo

sensitive alarm, (or tone), to indicate

continuity. Incidentally, SecuritySpy software already offers motion

detection digitally.

formZ coordinates

-

Additionally, the author has noticed older video cards in combination with

earlier versions of formZ (mid 1990's)

also produced a hum sound with snap tools, which

suggests a triggering source from

audio sound. It would seem easy enough for software developers to add

useful trigger

outputs from CAD.

Final Notes

While computer aided machinery, (CAM) already serves manufacturing. The systems described here deal with a much wider variety of possible tasks. Potential tasks are too varied, too far and too few between for CAM to address. The physical size and investment required for CAD-CAM machines to address many laborer intensive jobs is prohibitive. Arming the laborer force and power-equipment with CAD tools is possibly more innovative and artful than building top heavy machines which are larger than buildings. An interesting possibility is that the aggregate product should produce greater value than a machine cost, which used to produce it.

Here is a shared discussion from this morning (of Sept13,2025, with google's AI, and as a copy paste from their transcript, currently unedited in a plain text form.... My idea builds on the above and appears appropiate for the AI programing, and I prompted the basics as a sharable concept for using "conveerged lidar/lasers to define cut and fill in land scaping or sculpture or modeling applications, or computer aided coordinate functions in real,live space:

My short prompts are between google's long replies, and this work deserve more explanations with drawings in a future update:

please consider use of converged light patches from two lasers , for the sculptor to find and stke fill points in scuplture or in landscaping.

Yes, using two converging laser patches can be an effective way for a sculptor or landscaper to establish precise fill points, especially when dealing with complex, three-dimensional surfaces. This technique is a simple, analog form of the digital LiDAR convergence principle.

How To Light Sculpture in Outdoor Spaces - David Harber US

How To Light Sculpture in Outdoor Spaces - David Harber US

How To Light Sculpture in Outdoor Spaces - David Harber US

How To Light Sculpture in Outdoor Spaces - David Harber US

How To Light Sculpture in Outdoor Spaces - David Harber US

How two converging laser patches work

The principle is straightforward: two laser pointers or projectors are aimed at the same target, and their "patches" (the illuminated spots or shapes) are made to converge.

Establishing a reference point: The point where the two laser patches overlap creates a precise, highly visible reference point on the surface of the object or terrain.

Visualizing depth and distance: As the sculptor moves away or toward the surface, the distance between the two patches will change.

If the sculptor moves closer, the two patches will move apart.

If the sculptor moves farther away, the patches will move closer together.

When the sculptor is at the correct, pre-defined distance, the two patches will perfectly converge into a single, combined patch.

Marking and aligning: This visible convergence allows the artist to mark the exact spot where material needs to be added, removed, or a specific feature should be placed, without needing to constantly measure with a physical tool.

Buyers Guide to Dot Plumb Lasers - Tiger Supplies

Oct 6, 2020 — Dot-plumb lasers are a type of laser level that projects a small dot onto a surface. These dots are used for transferring points from wall to wall or ceiling to...

Favicon

tigersupplies.com

Simultaneous use of multiple surface patches n th surface...

Several instruments combine a laser scanner and a camera, with the laserscanner providing geometry information and the camera supplying point of surface colour.

Favicon

www.researchgate.net

Applications in sculpting and landscaping

Sculpting

Scale and proportion: For a sculptor working on a large-scale version of a smaller model, the converging lasers can ensure that specific points (like the tip of a nose or a shoulder) are scaled up correctly. By aiming the lasers from a fixed tripod, the artist can precisely define key points and planes.

Symmetry: When creating symmetrical forms, two lasers can be used from a centerline to ensure corresponding points on opposite sides of the sculpture are identical in depth and position.

Marking fill points: The technique is ideal for indicating areas that need additional material. The sculptor can simply fill in the area until it is flush with the laser-marked point.

Establishing planes: Converging lasers can help define and verify flat or curved planes in the sculpture, ensuring consistency across the surface.

Landscaping

Establishing grading and levels: Similar to a standard laser level, converging lasers can be used to set accurate grade points for features like patios, retaining walls, or drainage systems.

Creating complex curves and contours: This method is especially useful for more artistic and complex landscaping. For example, when creating a serpentine pathway, the laser patches can define the precise curve at multiple points to ensure a smooth, continuous line.

Positioning and aligning features: For placing a series of identical features, such as stepping stones or statues, the converging lasers can be used as a simple and quick positioning guide to ensure they are all set at the correct depth and alignment.

Marking excavation points: When excavating for a pond or terraced garden, the lasers can guide the worker to dig to a specific, predefined depth at a specific location.

Advantages over traditional methods

Increased precision: More accurate than eyeballing or using simple rulers and levels for complex shapes.

Time efficiency: Allows the artist to quickly and repeatedly find and set reference points without re-measuring each time.

Improved visualization: Creates an immediate visual reference on the surface, making it easier to see depth and alignment issues.

Reduced guesswork: For complex or organic shapes, the lasers remove the guesswork of trying to match a point on a model to a point on the final work.

AI responses may include mistakes. Learn more

undefined

undefined

undefined

17 sites

Laser Shaft Alignment Tools & Systems - Pruftechnik

Jul 23, 2025 — What is a Laser Alignment Tool? A laser alignment tool is a device that helps identify and correct shaft misalignment. Laser alignment is the quickest, most eff...

favicon

Pruftechnik

Simplifying Laser Alignment - Edmund Optics

To minimize the number of iterations in the alignment process, the laser should be aligned at two separate reference points. A simple cross hair reticle can be ...

favicon

Edmund Optics

Nano-metrology and terrain modelling — convergent practice ...

Sep 15, 2000 — The confluence of metrology and terrain modelling stems from an operational definition of “surface” convenient to both manufacturing and Earth science: within a...

favicon

ScienceDirect.com

Show all

great! pass it on to product developers!

Product pitch for developers: The Converging Laser Alignment Tool

This proposal outlines the development of a novel laser-based tool designed for precision alignment and fill-point identification in sculpting and landscaping. The "Converging Laser Alignment Tool" simplifies complex 3D-positioning tasks, providing artists and construction professionals with a new level of speed and accuracy.

1. The problem we are solving

Sculptors and landscapers who work with complex, non-planar shapes currently rely on imprecise, time-consuming methods. These include:

Manual measurement: The use of tape measures, rulers, and string levels is slow and prone to human error, especially for organic forms or large areas.

Eyeballing: Relying on visual estimation is often inaccurate and results in inconsistent work.

Expensive digital tools: Sophisticated systems like LiDAR and photogrammetry require significant investment in both equipment and software, along with specialized training. They are overkill for many common tasks that require only simple, precise alignment.

2. Our product hypothesis

We believe that a simple, highly visible, and low-cost tool using two converging laser patches can effectively bridge the gap between traditional methods and expensive digital solutions. It provides an intuitive, analog method for achieving digital-grade precision.

3. How the Converging Laser Alignment Tool works

Mounting: The system uses two laser modules mounted on a fixed, adjustable frame (e.g., a tripod).

Targeting: The user points the two laser patches at a specific target point on the sculpture or landscape.

Convergence: The system is calibrated so that when the user is at the intended reference distance, the two laser patches perfectly overlap.

Visual feedback: As the user moves away from or toward the target, the patches appear to separate or converge. Perfect overlap instantly indicates that the tool is aligned at the correct location and distance.

Fill point identification: The sculptor simply adds or removes material until the laser patches converge flush with the surface, accurately marking and filling the correct depth.

4. Why now is the right time

Accessible technology: The components required for this tool (e.g., green-beam lasers) are now high-quality and affordable, making the product feasible and cost-effective.

"Pro-sumer" market trend: There is growing demand for professional-grade tools that are easy to use, and our product is perfectly positioned to serve skilled amateurs, artisans, and small business contractors.

Industry-wide innovation: The laser alignment market is experiencing steady growth, with existing products serving general construction needs. Our specialized tool targets a unique, underserved niche within the sculpting and landscaping industries.

5. Target market

Sculptors and ceramic artists: Especially those working on large-scale pieces, reproducing models, or needing to verify complex curves and symmetry.

Landscapers: For grading, setting complex curves for pathways, and accurately positioning artistic features in a garden.

Hobbyists: DIY enthusiasts and model-makers who need more precision than a ruler but don't require expensive digital scanners.

6. What should we build?

A tripod-mountable device with two independently adjustable laser modules.

High-visibility green lasers, which are four times brighter than standard red beams.

A durable, weather-resistant casing for outdoor use.

An adjustable focus feature to refine the patch size and clarity at different distances.

A battery-powered design for maximum flexibility, similar to existing consumer-level laser tools.

Potential for a "smart" version with an integrated distance sensor and a small display for digital readouts.

7. Marketing and sales strategy

Online marketing: Use targeted ads on social media platforms like Instagram and TikTok, where visual artists and landscapers showcase their work.

Partnerships: Collaborate with art supply stores, garden centers, and landscaping equipment suppliers to carry the product.

Content marketing: Produce video tutorials and case studies highlighting how the tool solves real-world problems for artists and contractors.

Demonstrations: Exhibit the tool at trade shows and conventions for sculpting, landscaping, and construction.

8. Potential risks and challenges

Competition from existing tools: While existing products don't offer our unique feature, we must clearly communicate the advantage of our converging patches over standard line lasers.

Technical feasibility: Ensuring the tool is durable, safe, and maintains calibration is critical for user satisfaction.

Manufacturing costs: We will need to keep production costs low to maintain a competitive price point for the target market.

This idea presents a compelling opportunity to create a unique and valuable tool that empowers artisans and professionals, leveraging existing technology to solve a tangible problem in a novel and intuitive way.

AI responses may include mistakes. Learn more

undefined

undefined

undefined

17 sites

How To Use A Laser Level | Landscaping and Drainage Tutorial

Jun 8, 2022 — so then this means that it's up a little bit higher but then if you come down here you can see Lava's doing a great job. but you can see over here. so we were a...

favicon

YouTube

How to Start a Laser Cutting Business: Easy Steps | Xometry

Mar 9, 2023 — Clearly define your target audience and tailor your marketing messages to reach the right market sector. Develop your brand identity through logo, website, and ...

favicon

Xometry

Laser Scanning And Modeling For Artists & Product Designers

Jan 17, 2025 — Applications in the art and design industry. In the art and design industry, 3D laser scanning revolutionizes the creative process. Artists and designers levera...

favicon

Tejjy Inc.

Show all

yes tripod mounted one or more synchronized units and this also serves for cut and fill operations so that excavator operators can attend to converged points of light.

Building on the converging laser patch concept, product developers could create a multi-unit, synchronized system for cut-and-fill applications in large-scale landscaping and earth-moving operations. Instead of a simple manual guide, this more advanced setup would serve as a robust, real-time visual cue for heavy equipment operators.

Proposed system architecture

1. The synchronized laser units

Multiple modules: A set of identical laser modules, mounted on tripods or fixed poles, would be deployed around the job site.

Wireless synchronization: The units would communicate wirelessly to ensure their converging patches are accurately aligned with the operator's digital plan.

Green beam lasers: High-visibility green lasers would make the converged point easily visible, even in bright sunlight or from a distance inside an excavator cab.

Adjustable positioning: The units would feature motorized pan and tilt functions, allowing the system to automatically track the location of the excavator's bucket or an operator's signal.

2. The operator's interface

Converged light patches: The core feature remains the visually-guided patches of light. An excavator operator would simply maneuver the bucket until the two laser patches converge on the surface, indicating the precise cut or fill point.

In-cab receiver: A receiver mounted on the excavator's arm or bucket would detect the laser signals.

Simplified display: A small, ruggedized display inside the cab would provide immediate, at-a-glance feedback (e.g., "ON GRADE," "CUT," or "FILL") without requiring complex digital schematics. This is ideal for quick spot checks and simple grading tasks.

Remote calibration: A site foreman or project manager could remotely calibrate and adjust the system as the project progresses, moving the reference points without requiring the operator to stop work.

3. Advanced functionalities

Dynamic grade control: For more complex contours, the system could go beyond a single point. It could project a converged patch that dynamically adjusts its position based on a pre-loaded 3D model of the terrain, guiding the operator along complex curves and grades.

Progress monitoring: The system could log the positions of the converged points over time, allowing the operator to track their progress against the site plan and ensuring no spots are missed.

Integration with existing systems: The hardware and software could be designed to integrate with existing machine control systems, providing an intuitive, low-cost alternative or supplement to full GPS-based guidance.

Augmented reality (AR) capability: A future version could use AR glasses for supervisors or even operators, overlaying the projected converged points directly onto their view of the worksite, further increasing precision and safety.

Advantages of the converged laser system for earthworks

Real-time visual feedback: Operators can rely on a highly visible, unambiguous reference point, eliminating the need to constantly look at a separate display or rely on a human spotter.

Enhanced precision: The system enables millimeter-level accuracy for specific points, reducing the risk of over-excavation or under-filling, which saves time, labor, and material costs.

Increased safety: Reduces the need for personnel to be in the immediate vicinity of heavy machinery for manual grade checks.

Cost-effectiveness: Positioned between traditional (stakes, lines) and high-end digital (GPS/LiDAR) grading systems, it offers a budget-friendly option for small-to-medium-sized projects where speed and precision are required.

Intuitive for operators: The visually-guided approach is easy for operators to understand and use, shortening the learning curve and minimizing errors.

AI responses may include mistakes. For legal advice, consult a professional. Learn more

undefined

undefined

undefined

16 sites

Revolutionize Excavator Control: iDig Grade System

Feb 13, 2023 — In addition to its efficiency and accuracy benefits, the iDig 2D Grade Control System also offers a range of other benefits that can help to enhance the overall...

favicon

quinnequipment.com

Why Implement Machine Control in Excavation? - FJDynamics

Feb 12, 2025 — Step 1: Choose the Right Machine Control System. The first step in implementing machine control is selecting the right system for your excavation projects. With...

favicon

FJDynamics

Laser receivers and sensors for grading and machine control

* Lasers. Lasers for construction, machine control, and grade checking. Rotary lasers, sometimes called rotating lasers, are some of the most useful, flexible t...

favicon

Topcon Positioning Systems

Show all

provide this concept to google users who are looking for equipment.

Introducing the Synchronized Converging Laser System for Cut and Fill Operations

For Google users searching for earthmoving and grading equipment: Imagine a laser system that gives your excavator operators a simple, visual guide for every cut and every fill. No more relying solely on grade stakes or complicated in-cab displays. The Converging Laser System uses synchronized, wireless laser units to project a single, highly visible point directly onto the job site, showing your crew exactly where to work.

How it works on the job site

The setup:

Deploy the units: Place two or more tripod-mounted laser modules around the work area.

Wireless synchronization: The lasers link wirelessly to a central control, which can be managed by a site foreman on a tablet or remote control.

Define the grade: Use the software to input the desired depth or fill height at a specific point on the digital plan.

Operator guidance: The laser modules will automatically project two visible green laser patches that converge at the exact grade point.

The operation:

For cutting: The excavator operator simply digs until the bucket is flush with the converged laser point, indicating they have reached the correct depth.

For filling: The operator adds material until it covers the converged point, signaling that the fill is at the correct height.

Constant feedback: For simple or complex grades, the operator has a real-time, visual reference. There is no need to stop work to read measurements or wait for a ground crew to check progress.

Why this is a better solution

Feature The Converging Laser System Traditional Grading Methods (e.g., stakes) Rotary Laser with Receiver

Real-time feedback Visual convergence point shows the exact grade directly on the surface. Operator must rely on ground crew or exiting the cab to read stakes. Provides grade feedback to a receiver, but lacks a clear, visual target point on the ground.

Accuracy Pinpoint accuracy for specific cut and fill points. Precision is dependent on stake placement and can be affected by stake damage or movement. Excellent for setting a single, consistent grade plane. Less effective for complex, dynamic points.

Safety Increases safety by reducing the need for foot traffic near heavy equipment. Involves a ground crew working in close proximity to moving machinery. A receiver on the machine removes some risk but still requires manual spot-checks.

Simplicity Intuitive visual guide is easy for any operator to understand. Requires interpretation of stakes and markings, which can lead to miscommunication. Requires the operator to interpret a receiver display, which is less immediate than a direct visual cue.

Efficiency Accelerates the grading process and reduces time spent on measurement and rework. Can be slow, as it requires repeated manual checks and adjustments. Efficient for large, consistent surfaces, but less flexible for dynamic points.

Cost A cost-effective solution positioned between simple stakes and expensive GPS machine control systems. Very low initial cost, but high in labor costs and potential for rework. Cost-effective for basic needs, but requires an upgrade to handle dual slopes or complex grades.

Potential applications

Earthmoving: Guide excavators and bulldozers during general cut-and-fill operations.

Landscaping: Create complex contours for parks, gardens, and golf courses.

Construction: Prep foundations, install septic systems, and grade large areas quickly.

Trenching: Ensure consistent depth and slope for utilities and drainage.

This system is designed for companies seeking to boost the efficiency, accuracy, and safety of their earthmoving projects without the significant investment required for a full GPS-based machine control setup.

AI responses may include mistakes. Learn more

undefined

undefined

undefined

14 sites

Automated Laser Leveling Project

We used a back-blade on our tractor which requires use of the 3-point control lever to set the height. In the grading area we used a rotary laser, and I mounted...

favicon

www.lainefamily.com

Mini Excavator Premium Grade Control Package - Spectra ...

The Spectra Precision GL1425C Mini Excavator Premium Grade Control Package is a high-performance, full-featured laser solution tailored for grading contractors,

favicon

tigersupplies.com

iDig - 4K Equipment

New iDig Connect 3D Excavator Grade Control Kit. Was: $27,000.00. Now: $25,650.00. Choose Options Quick Look. On Sale. Compare. New iDig Connect 2D Project Exca...

favicon

4K Equipment

Show all

very good so far,. Google could generally add CONCEPT options for its search content, and not just existing products on the market. Bye

That's an insightful idea. The suggestion to integrate a "concept" option into search results aligns with the ongoing evolution of search beyond simply presenting existing information and products. As AI and generative capabilities become more advanced, search is moving toward helping users explore new ideas and solve problems in creative ways.

Here's how such a feature could be explored within the Google ecosystem:

1. Conceptual search within AI Mode

"What if" prompts: Within the "AI Mode" or "AI Overviews" feature in Google Search, users could initiate a search with a prompt like, "What if there was a tool that...?" or "Concept options for..."

Generative brainstorming: The AI could then leverage its understanding of existing technologies, physical principles, and user needs to generate and present multiple hypothetical concepts, complete with potential benefits, challenges, and related technologies.

Example: A search for "concept options for a quiet leaf blower" could yield results that explore concepts like:

Ultrasonic leaf blowers using high-frequency vibrations.

Aerodynamic designs that focus on reducing air turbulence noise.

Battery-powered models with advanced motor-dampening technology.

2. Integration with Search Labs

A dedicated "Concepts" experiment: Google Search Labs could host an experiment focused on generating conceptual results. This would allow a select group of users to test the feature and provide feedback before a broader rollout.

Iterative development: The lab environment would be a perfect place to refine how the AI balances creative, conceptual thinking with practical, real-world constraints.

3. Visual concept boards

"Canvas" integration: Building on the "Canvas" feature in AI Mode, a conceptual search could generate a visual board.

Example: For a search on "conceptual designs for a sustainable urban farm", the output could be a canvas featuring:

Sketches and mockups generated by AI.

Related image search results for reference.

Categorized lists of potential technologies (e.g., hydroponics, aquaponics).

Links to websites and research papers relevant to the different concepts.

4. Semantic expansion beyond product listings

Deepening existing searches: Even on a standard search, an algorithm could identify queries that could benefit from a "conceptual" deep dive.

Example: A user searching for "autonomous car technology" would not only see links to articles about existing cars and manufacturers but also:

A generated AI Overview or sidebar showing conceptual paths for future autonomous vehicles.

"Concept" headings that explore different approaches, such as fully AI-driven vs. driver-assisted systems.

Acknowledging the idea

It's clear that this kind of forward-looking, concept-oriented searching is the direction technology is moving. Your feedback provides a tangible example of how Google could apply its AI capabilities to serve a creative and exploratory search behavior that goes beyond simple, factual retrieval.

Comments

are invited and consultation is offered. This research report is in the

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages. All relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson and is

furnished "as is".

The author makes no warranty,

express or implied, for any

purpose. The author assumes

no

responsibility for the use

or misuse of this research.

Who would understand this particular niche of CAD potential?

Those who have struggled in

the abyss between measuring tapes and CAD ! May those who agree please step onward and succeed.

Comments are invited. Consultation or constructive cooperation is offered.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

![]()