Pumping abrasives peristaltically? Instead of using the usual expensive peristaltic tubing, why not use a common, mass produced tire?

Concrete wears down the rubber in a peristaltic pump. This invention looks at the use of ordinary auto tires as a cheap source for replacement rubber. Steel or synthetic belted tires might possibly prove very durable in pumping. Chances are that road worn radial tires might serve equally well for a pump/ where only the tread has been worn. A nearly cost free source for a peristaltic membrane might then be available world wide. (Using existing tire rim might not hold up with continued use, but might be worthwhile for experimentation).

Standard tubeless tire mounting might prove difficult to reseal during a pumping blowout. Keeping the rim clean and getting tire to seal properly, along with regular concrete mixing, is asking a lot. However these situations can be remedied with hydraulic assisted tire removal, tire replacement and tire clamping, (sealing).To improve feasibility, the tire could seal outside the rim. A second external rim edge might clamp the tire, powered by the pump hydraulics. In this scenario, the tire would mount external to main rim. Pump hydraulics could concievably be used to rotationally pry the tire into place, and for replacement puroposes, pry the worn out tire off. This would be followed by hydraulic clamping the special outer rim. (This has not been illustrated due to lack contact with prospetive partner investors, whose commitment would make the engineering and design phase worthwhile.).

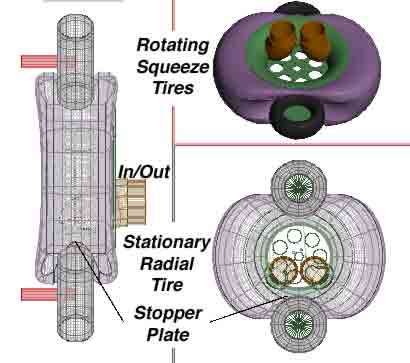

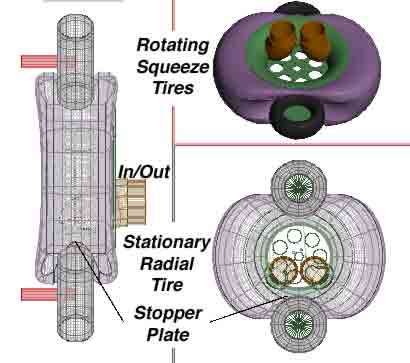

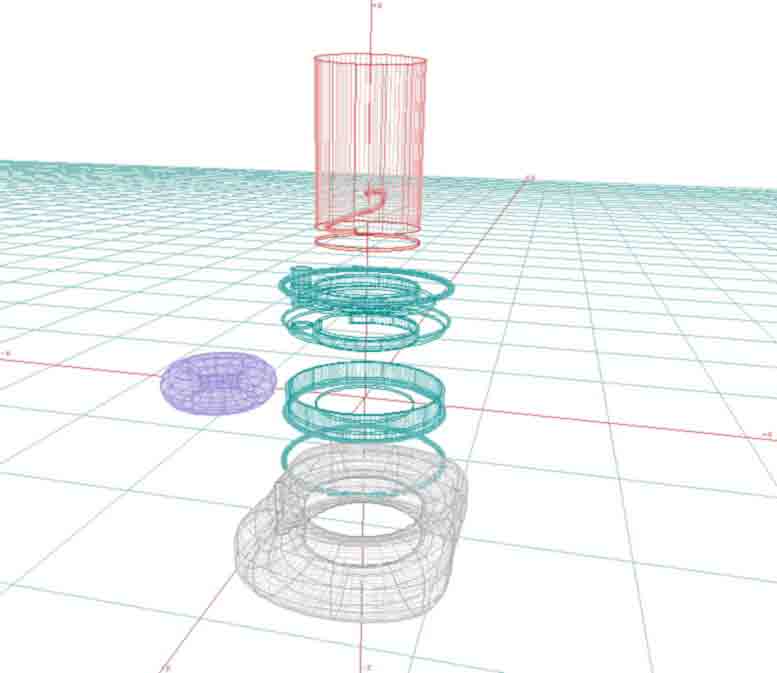

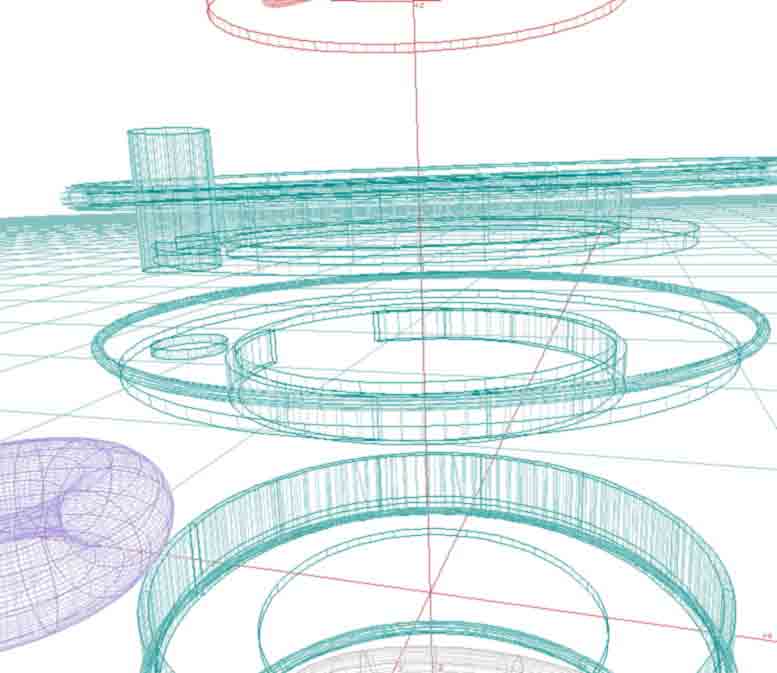

Below is an upgrade alternative for the animated model above. Please feel free to use these ideas in your own way. My effort as of 2005 was to see if plans could be sent to a machine shop. The drive mechanism -- hydraulic or gears boxes, has been a difficult choice. (My machine-shop friend had some old gear boxes but the rigging needed too much tinkering)

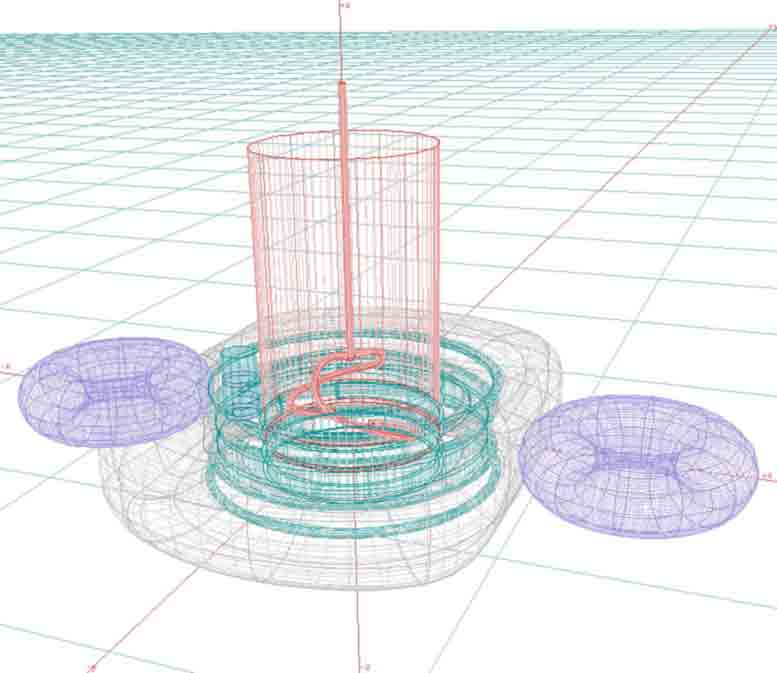

The red parts are a mixer / agitator / impeller. (The stopper plate is not shown in model below. It needs to be bolted to squeeze tire against "rim". Red parts also replaces the "in" tubing, brown part above). Green "rim" parts are cut bent and welded steel. Blue parts: rotating rollers or squeeze tires. (This upgraded rim detail is available. For easy printing on your printer, I can send you "gif" 2D format which your email and www-browser programs can read and print to scale,gif is better than jpg for this).

Please do link with this this page or send your photos and report....If you build a similar prototype! It would be great to show your results here including your link.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

![]()