The first illustration below demonstrates that better drainage can generally be improved by traditional arched drain paths, rather than commercially available full-round culverts. This page describes how a rural municipality might achieve better drainage at a low cost. (Yet additional halved culverts ganged together could multiply the drainage effect further). The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

Low budget, dirt roads present a unique challenge, especially when uneven bedrock or ledge is close to the road surface, (as in the picture below).

How are "floods of water" drained across a shallow road bed. (Where a road surface is situated close to uneven bed rock). Here is a strategy to reduce future, expensive washouts. The guarantee is the obvious multiplication of drainage effect, needed in special ledge-plagued circumstances. The half round shape of an arch concentrates the most drainage at the lowest point. Far more drainage is achieved, as compared with a full-round culvert. Please note that the author not an engineer, but rather a prototype builder-experimenter, who would gladly work with engineers.

Photo of heavy rain flood bypassing a culvert (indicated by red arrow), which could not be set sufficiently low due to bed rock (or ledge).

My feeling is that a more favorable method would combine a half-cut culvert-arch with fresh, ready-mix concrete. (Re-using and cutting the replaced culvert might reduce costs). High range water reducer is recommended, because it will significantly reduce shrinkage and normal concrete cracking. Fiber additives may also help reduce ultimate shrinkage. A normal road width is typically sufficient to result in some sort of ultimate cracking. An indentation can be impressed midway to serve as an "expansion joint".

1] Prepare the excavation to ensure the lowest possible footing for the arch, ( preferably below the controlled water line completely sweep-cleanly to the bed rock). Prevent or minimize water collection below the footing-- Clear out all "pockets" and large cracks in the bedrock, so that new concrete can ultimately rest on the bed rock.

2] Place several rocks in the excavation to brace the culvert-arch. Install the cut culvert .

3] After the above is carefully prepared, begin pouring the arch. Avoid kicking dirt on to the prepared footing areas.

4] Pour readymix concrete over footing area. Fill all low spots of the footing with concrete. "Walking" over the fresh concrete with boots will assist compaction of the fresh concrete and fill voids.

5] Start back filling and compacting, both the fresh concrete and edge dirt, simultaneously, to assist shaping the thick concrete arch.

6] Continue back filling, in short layers. A very small soil compactor could help densify the concrete while it also compacts the adjoining soil. Shaping the result as in the picture below will protect against ordinary frost heaving. Unusually thick ice build up causing blockage might call for additional remedies such as installation of small, empty tubing to be used for deicing by heating the empty tubing).

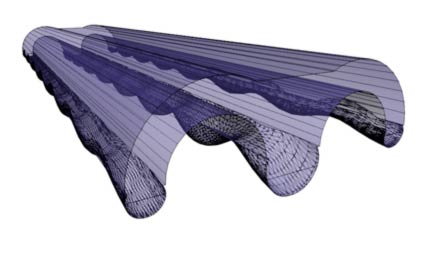

7] The road could allow small cars passage after leveling but keep heavy vehicles like trucks off it for at least 24 hours, (assuming that fast setting Type I-II Portland cement is used). Note- This method argues that steel reinforcement might not be needed, that primarily compressive strength is adequate.. The delivered concrete cost is possibly around equal to the cost of a new culvert. For perhaps 30% extra cost, two parallel arches could be fit into the site for double drainage capacity. A two-arch mini- bridge would be the result, without raising the road height and without a prolonged road closure. Doing just one arch would likely consume less than a normal load of concrete, so the readymix company could charge extra for "short loads". Therefore it would cost little-more to get a two arch "bridge". Here is a render at 8 inches thick (and it includes some "wavy" footing concrete to fill between wavy ledge).

In the above 3D model, 6.5 CY of volume is read, (a regular readymix truck load, not requiring the short load cost). Theoretically, one could use the old culvert as a concrete mold, by cutting it long ways and using both halves. Typically, the very bottom of a round culvert will rusts away, allowing water to erode the soil base away. Eventually, the culvert sinks lower and the road also drops away along the culvert. Rusted metal culverts might be cut with acetylene torches and used as a mold, because the rust is generally confined. (Proper ventilation must be provided, to avoid directly breathing exhaust from galvanized steel). Additional small holes might also be made and bent to form cleats. The metal culvert can be held by the mini- cleats, to prevent continual culvert-dropping into the water path, (as the culvert bottoms continue to rust away and typically rust primarily at the bottom. At such a future time as the whole metal fully rusts away, it would more likely then wash out and remove itself completely, instead of blocking the water path. The objective here is conservation of resources, instead of wasting new materials and new fuel expenditures of delivery and scrapping operations.

Ordinary ready-mix concrete has typically been rated between 2000 to 4000 psi crushing strength (depending on mix). Yet significant tensile strength is available only from added reinforcement. We see that plastic clearly has less strength than metal or concrete, but the elongation property is not problematic, since (well-compacted) surrounding soil can provide the typical 2000 psi load-bearing rating, like "hard-pan" (sub-soil). (So long as it is not effectively eroded or frost heaved). In the common example of 4 inch drain pipes, it is evident that the earth provides all the needed strength. An otherwise "weak" drain pipe curvature "molds" an earthen arch.

Regardless of choosing plastic, metal or concrete, some sort of footing is required because it's not as much the culvert wholly-rusting away as it is the (soil) footing which erodes away. (As a result of small rusted-out holes which allow water seepage to erode the footing away). If the top arch remained supported (and not dropped), it would hold just as well as a full round. Many a bridge over many a century have proven arch-durability, if given good foundations which are protected from erosion (of base-soil), and given solid-arch integrity. The arch or base/footing should rest below the ultimate flow path. This is almost impossible to predict with bumpy ledge. Yet i would expect it could be stabilized, given an adequate commitment to do so.

It will be interesting to see how well plastic culverts hold up to abrasion, over the decades. If abrasion will ultimately chisel through plastic, then those culverts will fail like metal culverts have. I would suggest that concrete arches might outlast all other culvert materials. Plastic drain products are no older than we are. The abrasive effect has clearly affected the steel demise in culverts (by hastening rusting).

(This article or page is written from the perspective of a moderately wet climate in Northeastern USA, by Bo Atkinson May 2008. A fifth generation Atkinson in the USA, still working with earth and stone. This page was prompted by a local spring time washout, in my small, rural town. A washout in this location has occurred nearly every year, because ledge or bed rock prevents the municipality from placing the culvert low enough to drain the flood. My solution is to make the bottom widest, as in the traditional-arched-bridge. Round culverts drain very little water along the rounded bottom, by comparison)

I love to brainstorm structural solutions. Send me your structural problems. boa1@pivot.net

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinsonlve a shared

This page prompted a question to the effect-- how would one best solve a shared stream bed and road way. Here is a picture from far away. My response follows below.

I would strongly consider converting a substantial fraction of the road bed into a "full" creek, while raising the road surface up to the average ground level, of the houses. The arch or vault concept should prove superior, scientifically and economically, when compared with full-round tubing. Yet powers that be may feel obligated to traditions and old ways.

I would cast concrete arc sections which are curved along two axes. These are essentially torus sections, of varied radii, but which share the same cross sections. As drawn, the heaviest cast section is about 300 KG, which is generally manageable with a modestly sized tractor. Thicker sections could be added on top which also seals the seams. Customized casting should not prove so difficult in our computer age. I have worked with smaller customized concrete castings for many years and would love to work at larger scales.

Naturally the scope of the project needs more analysis, in order to fine-tune the strategy. Engineers might prefer thicker concrete sections, which actually can be achieved in diverse ways. Also Access holes or "man holes" could also be devised, suitable to handle traffic. I can offer very competitive methods for casting, based on prevailing mix designs of your region. Arches require much less digging and might avoid blasting bed rock. Why not solve problems with more efficient means?

![]()