Fairing Out & Smoothing Ferrocement Or Curved Concrete Surfaces

Trowel smoothing can slow down some types of cement finishing, especially curved

and unbacked surfaces. Rollers can speed the job

up. Here are

some readily available methods

for

using

rollers to get

faired out smooth results quicker with ferrocement and curved concrete. I've

found paint style rollers with foam surface can give smooth results quickly.

Furthermore the rolling action compacts the cement well. Hard rollers

are well proven

for flat concrete slabs but lightweight paint rollers work best for ferrocement.

Rollers need modification. The trouble with unmodified paint rollers is with

absorbent material normally supplied and also

the weakness of the core. Also, the amount of available cushion is much less

than can be gotten from soft foam rubbers. Most important is an additional fabric

aid, (see 4 paragraphs down).

The cushion effect of a thick foam roller is the critical difference from hard metal, concrete slab rolling. The flattened part of the cushion presents much larger surface area of contact. Therefore the pressure is distributed and the rolled surface fairs out slight tolerances. Slight imperfections are automatically faired or graduated and therefore hidden. Considerable curvature is also accommodated by the cushion effect and streaks are not left on convex rounded surfaces. However an additional aid, described three paragraphs down is essential first.

I found and bought a ready made foam roller sold for tennis and golf courts. It is a roller with half inch thick, soft foam. By Midwest Rake Co, LLC,(large roller in photo above), they come in several widths. I added electrical tape for surface strength and it works well. Thick, soft paint rollers might also help you test the idea-- To test this idea, just leave the packaging plastic cover in place. Or wrap some food plastic on. The plastic cover should fit closely. If someone would fabricate and sell thicker foam rollers, I would recommend a full inch thickness or more (2 cm+). Also, I would think a sealed bearing would improve longevity and reliability for cement environments.

I've found that 1-3/4" EMT (44mm?) steel tubing is well matched to use on standard American paint roller holders. It won't deform like disposable paint roller cores. Very good foam tape for sealing windows, etc, is available in closed cell, non absorbent, self adhesive rolls. (EG: Norton type). Wider adhesive rolls are easier to put on, once the correct angle for wrapping is found. Foam rubbers, even closed cell varieties are too easily torn on the work site. Therefore I like to add a layer of resilient tape, like electrician's tape. Extra wide tape, again might give better results. The tape much better resists tearing while still offering the highly desirable cushion effect. Larger rollers still, with better bearings on both ends would be worthwhile investment for a busy job site. One more trick is tighter winding of tape at roller ends to"squeeze" a slight taper of the roller ends.This can help reduce the streaking tendency during use on flat or concave surfaces.

Yet another important innovation I came up with is to use fabric as

a parting agent, (aid to prevent lifting cement from surface).

Sticky cements, especially latex/ acrylic mixes, clay or lime,

cement foams

etc,

do tend

to

stick

to any tool.

Naked rollers become

uselessly coated in supper sticky mud phases. However fabric

can be used to "part" or

separate the moving roller from fresh sticky cement phase.

The

big effects of fabric is nearly zero suction builds between cement and

roller. Very

little

cement

passes

through to

stick on roller. Plenty of air gets in between.

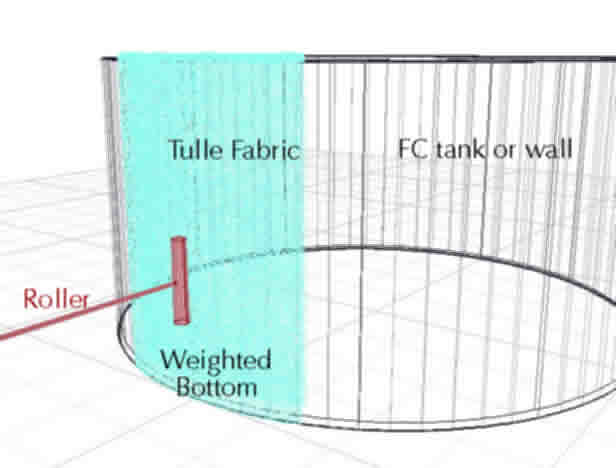

Several fabric types have been tried with varying effects.Tulle, stocking material and window screen have proven best so far. Different means of using fabric were also tried. Stiffer window sreen can be used as a movable mat. Lighter tulle especially benefits from a frame and handle, like a giant fiy swatter. (See picture above). Swatter like frames can be held with one hand and the roller with the other hand. Another experiment (picture below), made fabric into a loose tread on the roller, (a "sock" ). Thread/ socks save the time of handling separate fabric aids, but do tend to gum up faster. An air gun and or fine spray clear fabric nicely.

Nylon: Tulle is very light weight nylon netting with pencil-point size openings. Tulle can be stretched and anchored at edges of a fresh work area. It is sold in 8 ft to 2 meter widths at clothing fabric stores. Tulle material is so light that ittherefore presents very little surface to gum up. This quality assits fast, harmless pull off. I find that very jagged application of sticky mud is rolled very smooth in few passes back and forth. Ladies stockings have smaller mesh openings, closer, tighter weave, taper slightly, but do fit the paint roller quickly without having to sew (solve) seam problem. Bulky "sock seams" stamp creases in cement finish work. Fabricated stocking are seamless and smoother, but a little to tight for larger rollers. Nylons/stockings are a cheap way to test rollers if a used pair can be found, just cut ends to form 2 tubes. They work very well when new but are much harder to keepclean after some use. Nylons tend to stretch permanently. I needed to cut ends off to fit my tight roller.

Window sreen has oppenings slightly larger than tulle. However the "threads" or wires are much thicker. This naturally reduces the potential ventalation. Also, more cement fines can pass through and gum up the roller and screen itself. Nevertheless, window screen works faily well, needing perhaps just a little more intermitent cleaning. It's strength, durability and wider availabiltiy add to it's appeal.

Other fabrics might be worth investigating. There are various screen and netting materials availble.

************************************************************************

Next, below, is an example of using fabric "ceiling" to provide both a quick finish and catch all for cement applied to floor from above. Boards are shown backing up the fabric to allow pressure application and vibration of cement from above. Alternatively, the roller without use of backing board seemed to work just as well. The roller instead of backing board seemed to smooth out rough cement above fabric- below FC mesh. The roller method was easier.

Too little is known about actual test comparisons between traditional reinforcement, flat spiral loops and individual "O" rings. Rings appear to have interesting test possibilities. As a low budget single handed developer, I have very little opportunity to test the many ideas presented in these www pages. The testing cannot keep up with my my conceptual exploration.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson