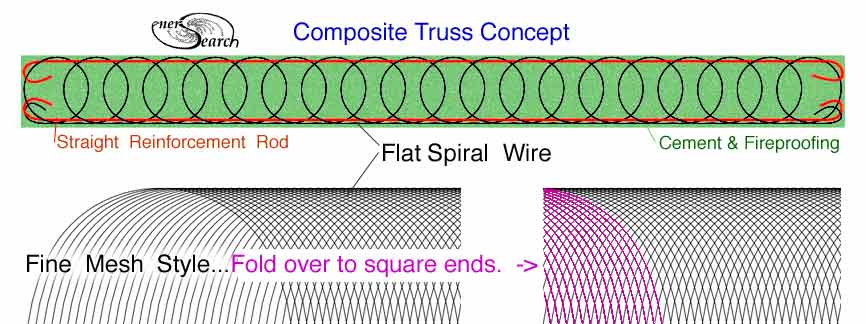

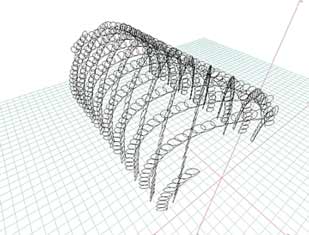

Flat spiralled, reinforcement rings, might prove an efficient framing element. The rings impart a truss quality to the framing members. A rafter, truss, joist or beam can be made with tapering sizes of rings to match specified stress points on structural members. Moreover, this method allows fitting to any sort of curvature which is difficult with traditional framing methods. From an economical stand point-- Fewer products produce many sizes of truss or beam, (better bulk discounts possible). Unspecialized labor can assemble this frame system, although the cementing and organization requires some skill. More recent work in this continuing study can be found on this link.

Simple circular binding of two reinforcement bars at beam edge is believed

to complete the truss effect, when a compressive material fills in between.

Ferrocement is a natural example, using steel wire and and steel bars. Concrete

beams and lightweight concrete floors or roofs are also potential applications

for this reinforcement system.

Recent examples of ring reinforced truss beams can be seen here.

It is hypothesized that near the maximum possible strength is attained for any given amount (weight), and any competitive design of same material, even competing against welded systems of equal steel content. No welding is needed at all in this system. Widely distributes tensile binding spreads out stresses and loads. While rings tie two edges together, the edges are also easily linked to adjoining surface reinforcement.

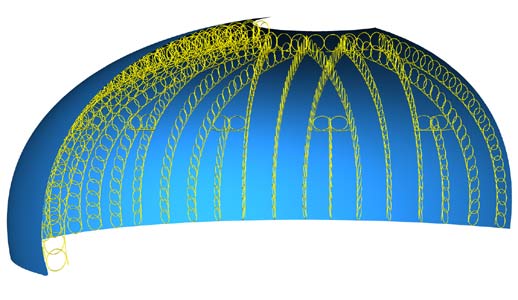

The first image represents spiral rafters which conform to curved roofing (like domes). Constructing a curved building is simplified using the spiraling framing and appropriate fastening. While Materials could include composites, (of plastic or stone), the entire framing and sheathing could otherwise be entirely of steel rods, tubing and sheet metal. This system is very adaptable for many structural purposes, given appropriate tooling.

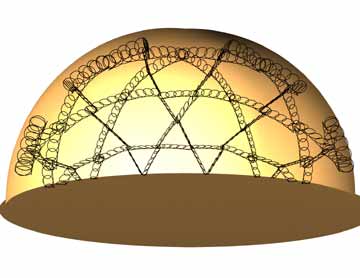

The second model attempts to place the frame-rings along a geodesic layout.

(It needs better geometric modeling). Sheet metal shingles, ferrocement or

other materials could fasten directly on to the pre shaped spiral rafter sections.

A great advantage with this system is that bending is easy and not wasteful

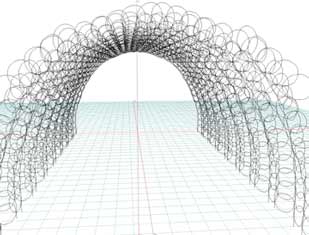

of cut scrap. Next a quonset

arrangement for spiral rings is modeled. Just the rings are illustrated in

the first two images.

Diamond configuration is one possibility for intersecting framing rafters. Intersecting of framing members offers mutual bracing. Triangles, diamonds and hexagons are some popular methods. Organic weaving patterns for structural members is an artistic adaptation and a link is planned here, visit again. Below: The quonset/ arch/ vault truss has bars installed to complete the truss layout of steel.. The red lines represent the bars and the black represent the flattened spiral rings..

Joining the metal bars and spirals is needed for exposed steel trusses. Joining at all intersections would be typical for trusses generally. However it is proposed that concrete incorporation of this truss layout will gain little if any overall strength from welding at intersections. It is proposed that all or most of the potential strength will derive from the compressive fill material. Concrete or ferrocement adaptions of the this layout would therefore save much labor if the concept proves effective.

Little is known about actual test comparisons between traditional reinforcement, flat spiral loops and individual "O" rings. Rings appear to have interesting test possibilities. As a low budget single handed developer, I have very little opportunity to test the many ideas presented in these www pages. The testing cannot keep up with my prototyping nor my conceptual exploration.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson