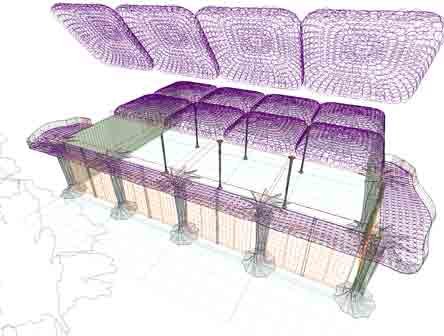

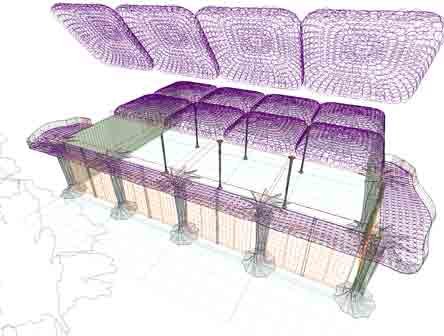

Concept for thin

shell vaulting which uses recycled auto tires as form work. Pictures of

actual construction using this system may follow.

Below is a mock up

of how individual tires will be held together using clamps. However

the steel wheel centers will be left in place. Sapling trees will be used

support the

form work. Rusty, recycled wheel rims might hold tires well

but cleats might be also welded to prevent rubber from slipping off. An

attempt to split rubber tires (picture below) without cutting steel belts

will avoid worker exposure to sharp metal while handling molds. Each

converted wheel will be supported on an individual pre sized pole

.

Above-- Mock-up

of converted wheels showing clamp to hold many together. Steel part

of wheel is missing in the mock up. Yet to be illustrated is the plan to

use sections

of fabric like burlap to

close

in the the mold

surface. A dirt loam coating will then be applied over the burlap to fair

out the surface. Local dirt as a mold release and as a simple texturing

agent should simplify interior finish. (After pressure washing, paint

can be

applied,

if

desired). Next Below is a housing

example which could implement this type of vault. The purple color

rings illustrate a ring reinforcement.

Standardized lab

testing of ring reinforcement to compare with other reinforcement systems

is of interest. As a low budget

single handed developer, I have very

little opportunity to extensively test the many ideas presented in these

www pages. The testing cannot keep up with my prototyping nor my conceptual

exploration.

Agricultural wire offers much

easier use but as a thicker gauge is less ideal than thin gauge welding

wire. More effort will be made to show examples. Here is an

example used in contoured wall construction, (sand molded tilt up method).

Here

is an example used in a stair.

Here is another example

of simple

ringforcement using heavier wire.

Step by step concept

for using ringforcement in a small (5m/ 15ft) dome.

The opportunity to

build the above vaults might also present a combination of needs and site

conditions as follows.

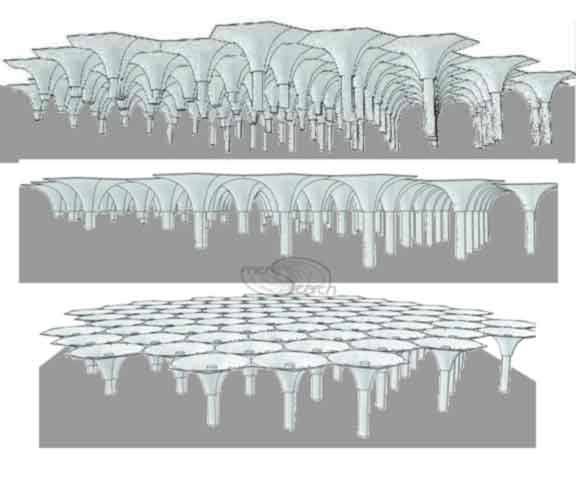

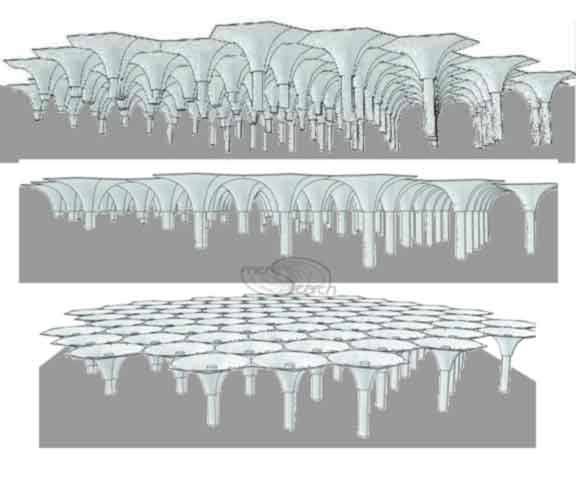

The following illustration shows variable height pillars which

are topped with hexagonal capitals.

Pillars

are poured concrete. Capitals are sand cast flared cones shaped to regular

hexagons on top. Picture below shows essential

shape. Capitols can be cast with reasonable tolerances and efficiency.

After installation, the hollows may be filled with economical concrete

and leveled.

A monolithic slab or other surface is then possible.

The hollow shell, hexagonal, cone like parts can be set upon

poured-in-place columns.

Additionally, spaces below floor could conceivably also be sealed off from

exhaust are. These partitioned areas could be used as cellar spaces and as

a solar heat exchanger space. In the case of solar heat, solar powered draft

schemes could be implemented.

Here was a web querry which reminded me of other applications, which i once promoted for development. Quoting an email (name withheld)-

"Hey, I found this image on your site and was totally intrigued. I’m looking into the concave/convex pavers/tiles for a project and this form caught my eye. Have you ever made a prototype? Any info or background to your idea would be appreciated...."

To which i answered:

"Absolutely, yes... My photos are still on 35mm BW film strips from the 80's, (never as yet digitized). They were easy via low-tech-low-investment-research means. I had several conceptual application concepts in mind. Perhaps too many detailed tangents to cover briefly. Yet i never did find contacts to develop more of an enterprise, (beyond small scale applications). In a sloped-paver application, one could install them with far less "leveling" required (As compared with squared systems). Sort of a networked-hexagonal-terracing could result -- Providing both an expansive stairway and also a robust concrete or tile mulch with two sized holes available from a single mold. Or furthermore, varied designs could introduce varied aesthetic appeal, even as elaborate as Escherian motifs ;-)

I do offer powerful CAD services including both mold detailing and also terrain modeling, (both newly-conceptual and also using strict, pre-existing terrain data, measured constraints, etc...) i would be glad to quote on a specific contract for this sort of work.

Bo Atkinson in Maine "

These quotes show that i respond to emails and usually in reasonable time. I do love doing design work delivered through the web" Creatives like myself do welcome paying jobs.

Too little

is known about actual test comparisons between traditional reinforcement,

flat spiral loops and individual "O" rings. Rings appear to have

interesting test possibilities. As a low budget single handed developer,

I have very little opportunity to test the many ideas presented in these

www pages. The testing cannot keep up with my my conceptual exploration.

Note: These pages are placed in the public domain and are furnished "as is". The author assumes no responsibility for the use or misuse of the concepts in this series. All authorities should be satisfied first, as might be required, by relevant laws, before any building proceeds.

Searching Synergy .... .... Free Exchange of Ideas

.... Free Exchange of Ideas

Enersearch was incorporated in 1980 but never materialized financially. A synergy of concepts were developed and are reflected in the pages of this series. The synergy continues as a single handed effort of Bo Atkinson, in Maine, USA.

Email comments welcome ~~~~~~~ boa1@pivot.net

Tel : 207 342 5796 . . . (Maine)

index.html