Part 1: Slack Wire Robot

Large Scale 3D Output Digitizer & Building Concepts

2008 : Digital implementation of Camera-Lucida for construction layout.

Newer: More information on ring reinforcement, also called Ringforcement.

Newer: Waterborne forming methods for producing dock-able modules are on this linked www-page.

2002 Page Below: Robot Builds Concrete Structure-- 24/7 Automation

A suggested system which:- positions, proportions, mixes, and places materials -as one step. Integration of the otherwise separate tasks could streamline work, promising greater creativity and productivity. This vision temporarily ignores the tasks of finish texture, plumbing and electrical installation, etc... These additional tasks await further consideration.

Text, illustrated design and Part 2 inventive content by Bo Atkinson

These concepts are given to the The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages. All relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson in hopes of inspiring further development.The ultimate objective is lowering construction complications generally, while at the same time multiplying customization potentials. Bo has worked with concrete as a small town contractor and sculptor for many years. Mastering concrete skills can be frustrating if you don't have the means to hire timely labor or to buy equipment. Here is a dream of a concrete power tool which one person could theoretically own and use (even alone). Computer technology has reached the point where this system could be readily built and tested.

Part 1: Slack Wire Robot

The inventive slack wire robot concept was suggested by Anne Ogborn, Software Engineer,who contacted Bo out of the blue one day. The whole concept and this www page took a while to refine. Internet serendipity calls us to move forward!

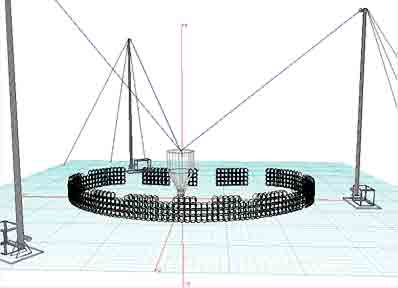

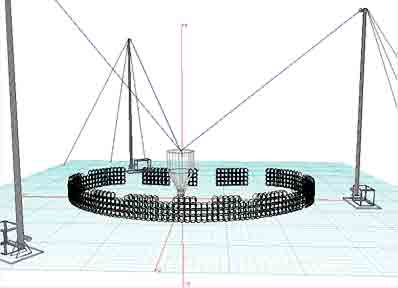

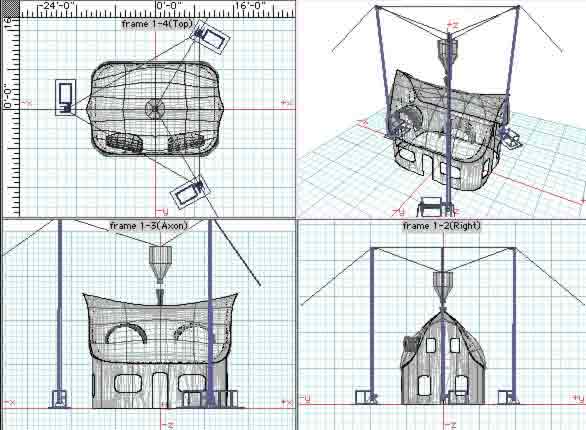

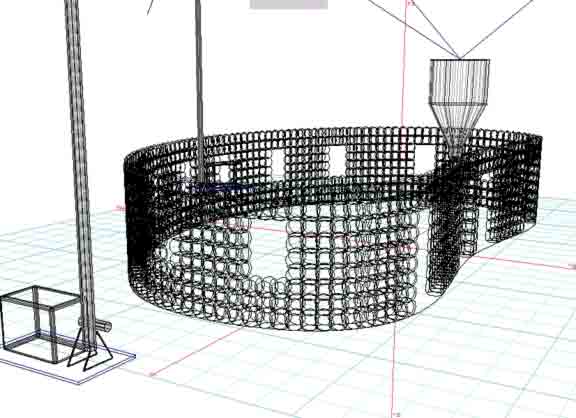

Computer controlled gear, emplaces structure. Hundreds of ordinary engineering problems need solving first but the computer components are generally available today. The systems described can be experimented with today at reasonable cost. This visualization only shows where existing component types can fit together into a workable whole. While other mechanisms might be promising, the one visualized addresses economy of development through minimal equipment usage. The three pole derrick cables, (slack wires), are reeled in and out to position a cementitious extruder. Annie suggested reeling information could be obtained much like a "computer mouse" rolling upon the pulleys. Another readily adaptable tracking and positioning system for the 3D extruding gear in real space is linked on this page. Highly customized shaping could become equally efficient as compared with simpler rectilinear shaping.

The "blocks" are formed in place by the suspended extruder, (slack wire robot). Here, each extrusion is referred to as a modular "block". Freshly extruded "blocks" can be placed to form course upon course, (similar to masonry construction). In masonry, solidified blocks permit immediate height gain. Fresh concrete needs support of some kind to gain wall height. Methods to substantially stiffen concrete are well known, (such as by use of much larger aggregates, use of fly ash and other additives like fibers. A yet further increase in stiffness may be obtained from fibers made into mini-rings which will reduce concrete slump still further). Fresh concrete of light enough weight could otherwise allow for this height gain, (without slumping). Concrete slump normally limits free standing formation due to slump caused by aggregate heaviness. Insulating aggregate (natural, manufactured or recycled) and various cement admixes may be designed to largely overcome slump and improve cement curing. A matrix of reinforcement rings partially acts as concrete forms, linking all parts of the fresh extrusion as one monolith.

Three directional linkage within each block and with adjoining blocks constitutes a highly distributed armature. Three directional linkage clearly outperforms one or two directional linkage. The inter block linkage provides considerable three-directional-stability in cured concrete. Combining tensile linkage, insulation and load bearing into one building block package greatly streamlines the automated process. A machine made to form one such block can conceivably be programmed to build thousands (assuming the attendant keeps up with supplies and command).

While four rings may be bent to form reinforcement for one single block

as a building component, there are yet other ways to achieve the

same reinforcement aims. Many blocks can be formed with long segments

of flat spiral or flat helical coils of reinforcement material as

pictured above. Only the ring reinforcement is shown, to transparently represent

how each block could link together. Each face of a cubic "block" is

provided a ring. Each ring is situated to link with rings of adjoining "blocks".

However, where blocks are stacked together in a wall, each block could

share and reduce the number of rings to advantage. All exposed faces of

each block are provided rings. However connecting block faces can share

a ring with neighboring blocks. For low rise structure, small gauge wires are assumed most

appropriate for economy and adequate

strength. Synthetic filaments are also worthy

of study, in search of overall economy and durability. Placement

of ring formations

as

drawn may be achieved with ring forming

machinery. In absence of such machinery, hand made versions have

already been built and studied internationally.

Large scale concrete structures will also likely benefit from this building technology. Many possibilities are conceivable, being most dependent on the scope of development. Dimensional analysis software would greatly help to determine optimum properties like material gauges, relative to types of concrete mixes to be used. 3D models (like those illustrated here), could quickly compare differing ring and admixture properties to identify the most worthy real world candidates. With this analysis software, design files specifying many alternatives can be readily compared. Here is a linked-page with the original publication of ring reinforcement included. Next below, yet a further interesting ring configuration is shown. Three rings aligned with X,Y & Z axes respectively, are joined at six intersections. In practice the the rings could be placed directly in arrayed matrices and stabilized by the concrete alone. Or the rings could otherwise be joined by "hog rings" or the like, in triplet-XYZ form as shown, in advance of the concrete aggregation.

Utilization of appropriate reinforcement bars might also be expected were engineering to deem them necessary. larger ring beams or the like were not included in order to make clear the ring elements. Longer than shown bars might or might not be ultimately deemed necessary, in that ringed bars could prove a superior construction elements altogether. The 3D rings are readily deployable, automatically. Here is a linked-page with more details on ring reinforcement.

.

The models suggested here are available for dimensional analysis study. Structural design and analysis software would provide a good basis to study ring reinforcement. A powerful modeling software (formZ by autodessys ) was used to draw the pictured models. It can transfer generic files to dimensional analysis software to analyze structural characteristics. Access to dimensional analysis software is sought by this writer who can not afford it presently. (Talk to me if interested 1-207-3425796, email: boa1@pivot.net ).

Method to produce ringed, adjustable mesh. (Ring production experiments).

Comments are invited. Consultancy or constructive cooperation is offered.

The content on this website, http://harmoniouspalette.com, is placed in the public domain only as a free exchange of ideas and as a "hard studied wish to serve life". The author assumes no responsibility for the improper use of the concepts in these web pages, as all relevant laws of life and local codes should be verified and observed before any building or experimentation proceeds. discussion is welcome, please write. Bo Atkinson

![]()

A wonderful, early history

of lightweight concrete is included in "Brunelleschi's

Dome" by Ross King. He mentions the ancient Roman Pantheon dome

having lightweight aggregate (pumice) mixed with, silica enriched

(pozzolana) concrete. Also noted is the Pantheon's inventive

use of integral voids (clay

vats: amphorae) along with recesses to improve load bearing.

(This book has 8 pages of notes with a bibliography). One of

Brunelleschi's greatest contributions

was an exceptional reduction in form work long used for traditional

masonry construction. Ring support for forming concrete is introduced,

following

this excellent example of reducing form work, hence lessening

the burden of human toil.

Computer controlled production contrasts "Mass Production". In stead of the same product manufactured in massive quantity, as little as one item is produced. "Multiform Manufacture" is custom manufacture, machine optimized.