I noticed an echo free dome after completing cement work below. This ferrocement dome has proven echo free, ever since. Musically inclined visitors agree that no echoes are heard. Coffer styled fire proof structure integrates framing, sheathing, and scaffold.

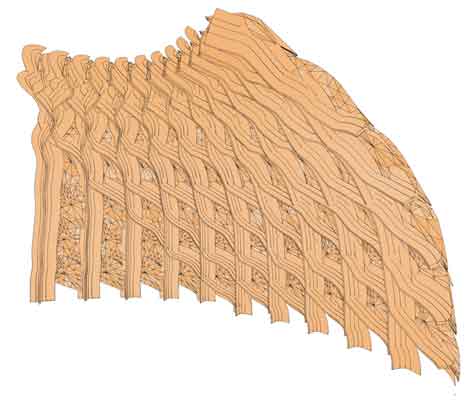

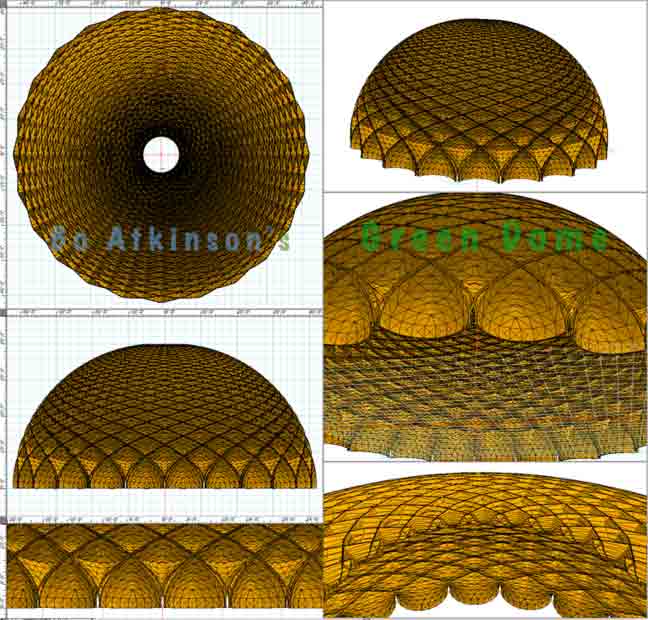

My purposes for building this was to experiment with "doubly curved surfaces. Through geometry, structure and ferrocement. (This favours thin walled, steel and cement composites). The echo free ambiance was a very rewarding result. This building plan began around Year 2000). Since that time, software tools have improved. Here is a 2012 prototype model:

My year 2000 geometry tools, (example below) was very limited

My own expectation is that a largely anechoic auditorium could be built using a hard surfaced interior. To achieve echo free ambience at a lower cost, (for large, clear-span structures). There seem to be some structural and budget advantages. The costs of fire safe, soundproofing usually requires additional skilled trades and considerable extra material costs. What are the desirable acoustical effects for music halls? Do we want resonance and polyphony? Can structure enhance music played within? Can we experiment with such effects by altering coffer shapes and sizes? Many questions can follow. Contact me for an interesting discussion.

![]()

As a creative, i work on a shoe string but love to experiment with structure. My additive-construction-method, for ferro cement was used here. I always look for minimal expense methods, in construction. Construction-quality for me is based primarily on the harmony with the bigger picture of life. Note the cheap scaffolding uses the dome itself, (in picture below).

Reduce material costs, used to soften sounds in a hard surface building. Keep budget more relaxed. Where the basic structure itself integrates the anechoic features along with the structural framing, of large dome spans. It is integrated framing or truss work which allows larger dome spans. Typical dome projects rely upon reinforcement in the skin alone. This reliance results in less efficient use of material. Additive coffers provide framing and sheathing in one basic unit.

The anechoic aspect was noticed around completion of the ferro cement work in the summer of 2006. Above picture: The last few coffers (or bee cells) are snuggled in, (molded into place). Photo below taken from ground floor viewing up through central opening in the second floor.

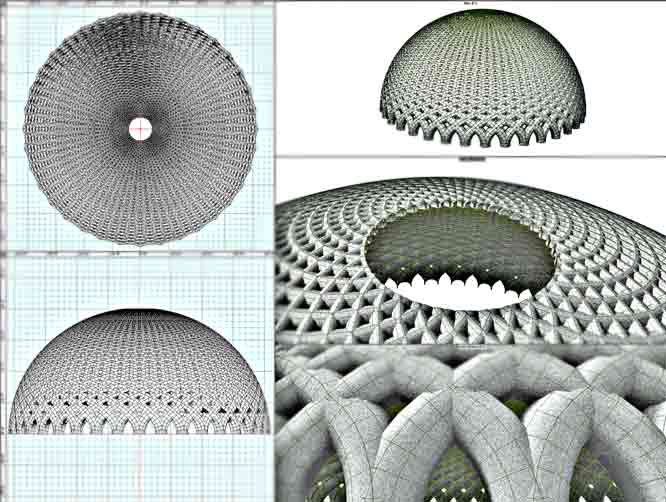

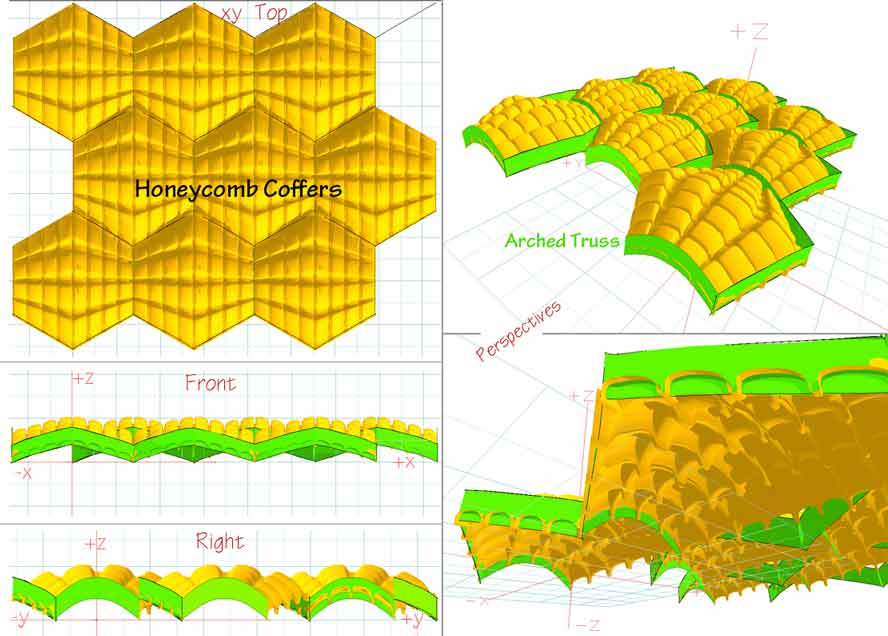

The second floor (below the dome ceiling) has integrated joists which intersect at 60º angles. (Or running in 3 direction). I continue to wonder about structure. Another aspect is the notion of "fractal vaults". Or coffers arranged into a larger vault or dome. Following are some 3D models to show this.

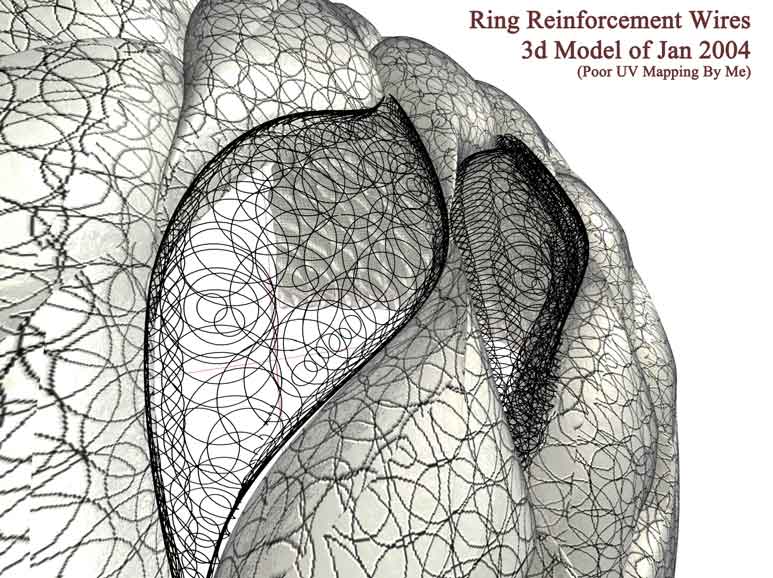

My search always continues for structural efficiency. Below follows yet another structural concept which more directly incorporates truss work. Without having to add straight-linear truss-reinforcement). It seemed to me that "channel beams" in the form of half cylinders (or arched channel, or half split tubes) should easily 'union' together. (Integrated structural components instead of woven components). Here are much earlier examples of my framing exploration. The next picture shows integrated channel structure in a dome.

Efficient structure is expected in these examples. In this example (picture above and picture below, both pictures: The concave surfaces face indoors. In this example (picture above and picture below, both pictures:This same 3D model uses many individual channels by crossing paths. Two of the individual channels are drawn below:

The next geometric model below shows these same tubes inverted. So that the the concave surfaces face outside! What use could this serve? My expectation is that it will serve as the best possible "green roof" function. Soil or equivalent can be held on sloped surfaces, (like any, well-made structural roof system).

The version above represents many planter indentations upon a surface of a concavely subdivided dome. Next concave and convex are compared.

Many structural subdivisions are conceivable. In all cases presented here, the interior surface does interfere sound waves which should reduce echoes. Which arrangements can work most favorably? Next is a simpler adaptation of soccer ball sections arranged in ring clusters. It can be formed and reinforced efficiently with ferrocement or concrete.

Miserly building experiments with ferrocement structures convince me that 'ball' or 'inner-tube' form work are the most cost savings methods, (for larger, clear-span, cementitious structures). I've 3D modeled a variety of clear span structures.

I would love the opportunity to study large, clear-span structural models, suitable for an auditorium. The picture below shows a proposed cross section for a large auditorium. 3D models of this extent take much more time to develop. (The essence of coffers is emphasized. Full truss-like boundaries are intended, but not shown).

New pages will eventually be added as modeling time permits. High-resolution pictures are available, ask me. Below was an early effort to model coffer divisions with arched truss works. (Actually, the truss sections are meant to form a larger dome structure, but fitting "fractal vaults" take much more computer effort and human time.

The effect of stalactites 'dripping' from ceiling is a natural outcome. I love finding natural results and a structural metaphor as well. This outcome relates to my earlier study. A re curve cable arch night serve more efficiently, in case echo-free acoustics are sufficient with coffers alone3. It is all an exploration of using steel with vaults and with coffers, to reinforce structures. Or, of using strong tensile members inside composite structures. In any event, stalactites predate and also appear very much like the classical anechoic structures used in experimental science. I wonder if integrating domed-coffers along with stalactites inside a huge vaulted ceiling will enhance polyphony. Let me know your thoughts.

Much more can be said about observations while using my dome building shown above. I never expected to 'finish' this building to high standards. Only the conceptual prototyping was developed to a large extent. My low income and under-employment explains the very rough finish in my work. I can't afford much effort or money to polish my prototypes. Creatives usually cannot afford building all of their own visions. You can see what other ambitions were realized on a shoe string, click here. Or why not avail from creative services? Consider consulting with me online. Buy consulting time for your own dreams, while supporting this kind of progressive service. My computer models might help convey your own dreams to your officials, to your engineers and architects. I even offer hard labor to speed up creative building projects (in stone, metal, glazing and varied green skills). My rates are very reasonable, click here.

Vault structures have traditionally been formed with stone or brick materials, without use of steel reinforcements. Gravity firmly held the stones or bricks together. Introduction of steel-reinforced structures has forgotten the advantages of vaults. Apparently, steel can provide advantages in building vaults.

My dome design intended to represent a tree grove. The coffers were meant to emulate leaves. Some earlier pages show the struggling construction phase. Hired help amounted to a few percent of the labor. I did everything else alone. See linked pages here. There are some earlier pages documenting my builder-progress, while building this prototype.

My creative glazing studies actually interfered with a better-more-standardized weather seals for the greenhouse section. (Haste made waste there, suffer for one's art). The structure handles this without problems because ferrocement does not rot. My research work will continue and provides some useful observations over time. We are not trying sell the place besides, or hide these findings.

Furthermore, one of my worse goofs was my failure to strictly follow my intended dome-slope/curvature, during my coffer installation. My circumstances were very crude and a more-logical protocol was out of my reach. Outside jobs distracted my focus. Better building-systems were too luxurious for me on a low budget. The main emphasis was experimental production. While each day demanded visible 'progress'. "Keep that hand on the plow."

It was not until the 5th course or row of coffers that the curvature implications startled me: The implication that my earlier coffers should have sloped more inwards. It was too late. So, my solution was to sharply adjust the angle in the 5th course. This abrupt 'adjustment' is seen in morning sunlight. Where the abrupt change of slope casts sharp shadow contrasts, instead of a more gradual dome shading gradient. At least a little extra head room was gained from the original lack of centering, during the building phase.

Above: I added some collar-tie-reinforcement inside, with steel cables attached to coffer frames. Below: Winter of 2011-2012, my steel workshop is finally getting organized:

After 3 decades of keeping these tools mostly outdoors.

I always tried to combine art, science and philosophy as one occupation. This was not marketable, but it did enable self-sufficient methods of living, with seasonal jobs to pay expenses, and also to recycle scrapped materials as much as possible, in the plentiful free time of the back woods. The all- demolishing powers of our world have always corrupted and crashed the progress of mankind, which is a fact almost unknown to the average person. A workable solution was dreaming up a "ship wrecked romance of life", trying to rebuild with the broken pieces, and this provided a new found freedom.

![]()